Grinding Mill Balls

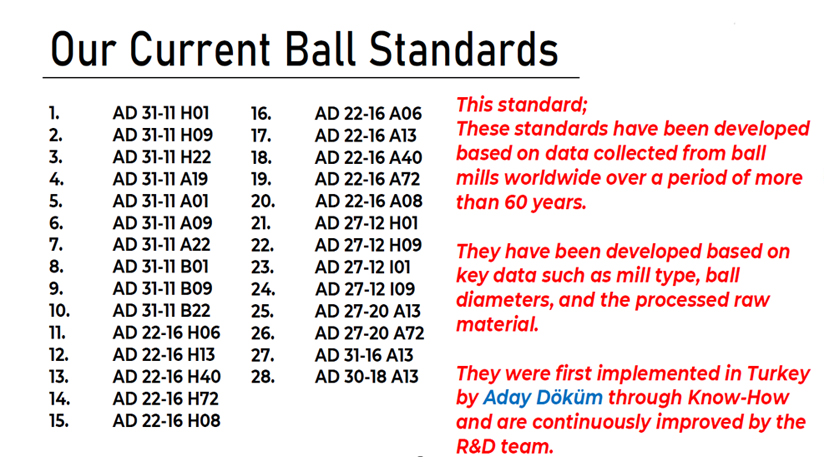

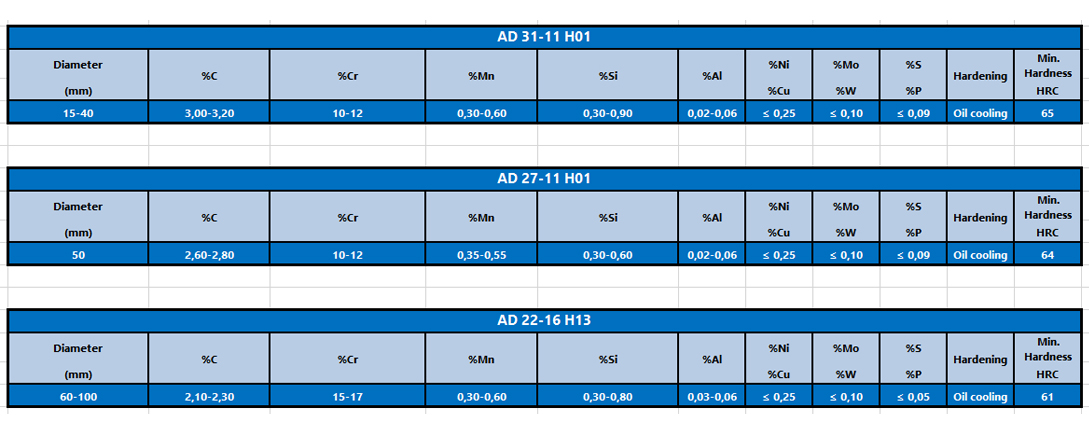

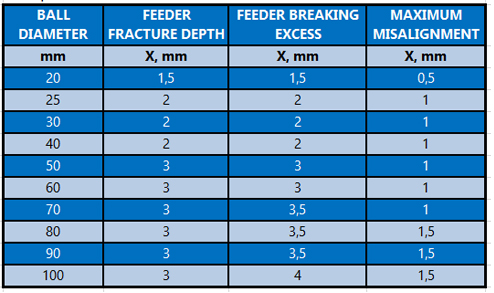

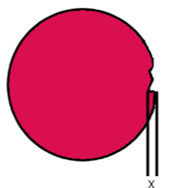

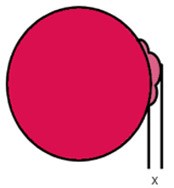

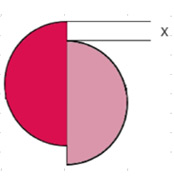

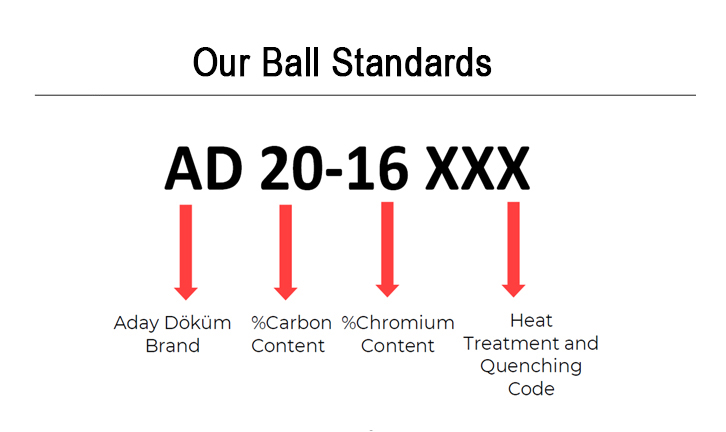

Aday Döküm has specific heat treatment standards prepared according to the size, chemical content, and raw material type of the grinding balls.